Product Features

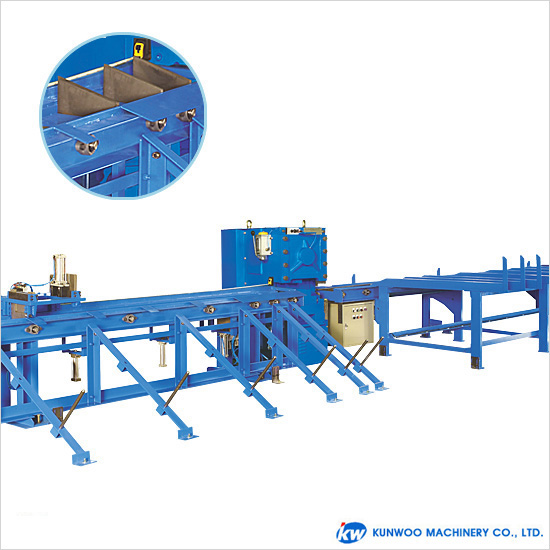

- When installing this machine connected with the manual rebar cutter, the productivity can be enhanced 3 times more than the existing manual type.

- The feeding & discharging of rebar is automatically controlled , by using the motor in the conveyor.

- The adjustment of measurement and clamping works can be available at a time at the place of the machine, which can improve the flow of works.

(The operator must move to the cutting distance in order to do the clamping works in the existing method.) - There is no tolerance of rebar length as the stopper is built strongly.

- The work efficiency & productivity are enhanced as the discharge of rebar is same as the automatic up & down method.

- The function such as forwarding, backwarding & discharging of rebar can be controlled systematically, by installing the sub-control box in the main unit.

Description

Product Specifications

| Power consumption (kw) | 8.25kw | Head unit | 3.75kw×1 |

|---|---|---|---|

| Feed conveyor unit | 0.75kw×3 | ||

| Compressor | 2.25kw×1 | ||

| Electric | 220V / 380V 3Phase | ||

| R P M | 27rpm | ||

| Feed conveyor speed | 39mm/min | ||

| Blade width | 166mm×80×35 | ||

| Cutting length (mm) | 500 (min) ~ 6,000 (max) | ||

| Loading capacity | 2,000kg | ||

| Dimensions (m/m) (L×W×H) | 18,000mm×2,600×1,350 | ||

| Weight (kg) | 6,000kg | ||

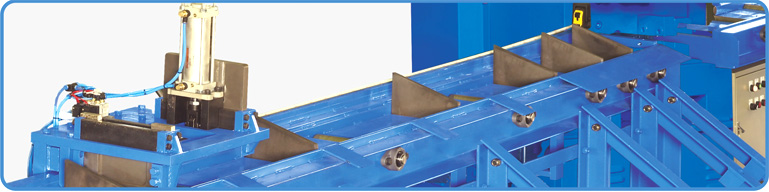

Up / Down method of discharge (Front discharge)

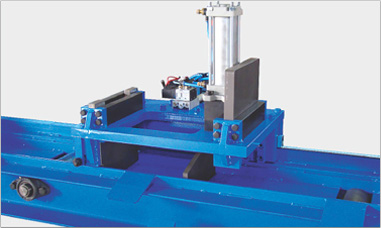

Stopper Device

Control Panel

Sub-Control Box

Easy control of measurement

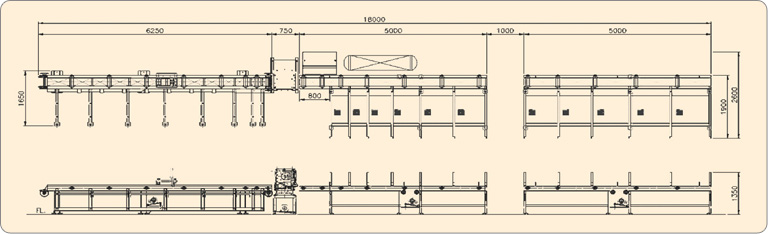

Plan