Product Features

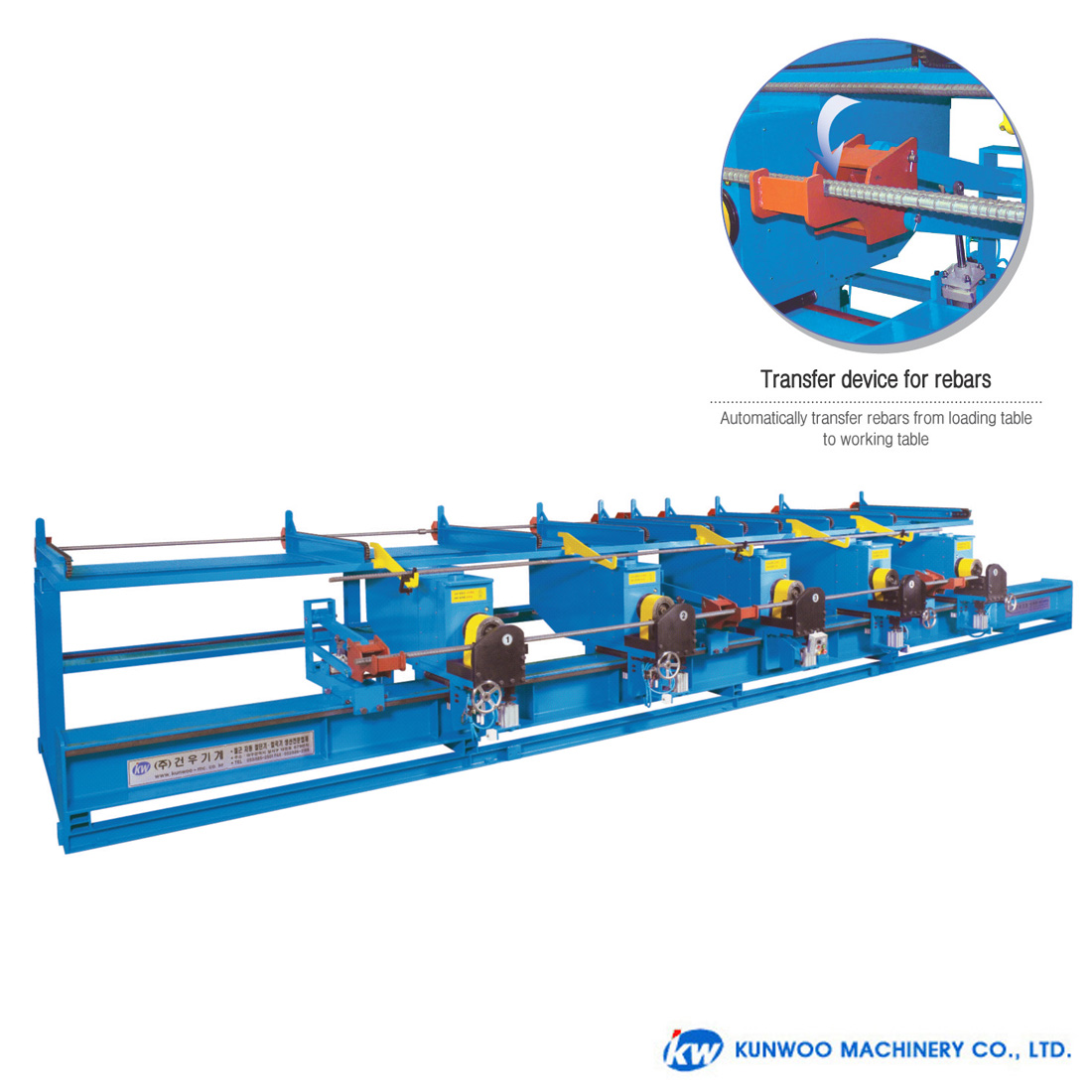

- The rebars are moved automatically from the supply table to the work table

The productivity of steel Bending may increase in comparion with the standing Machine by 4 through 7 times more - When it is needed to replace the roller during operation, you can change it by adjusting Sub Control Box without having to go to Main Control Box.

- This is easy to control so that even the unskilled workman can operate it with facility.

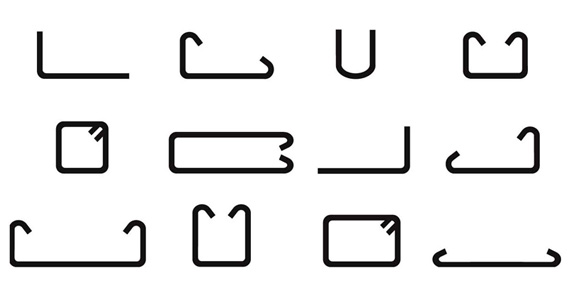

- It is easy to change the form of steel Bending into various other types. (Refer to the kinds of steel Bending.)

- All the parts and components of the entire machine can be manufactured 100% domestically.

So we can provide all the necessary parts and after-sales services. - A perfect Automatic steel processing Machine can be achieved with the combination of Automatic steel Cutting and Bending Machine.

- The head part of the machine can be moved through the special conveyor.

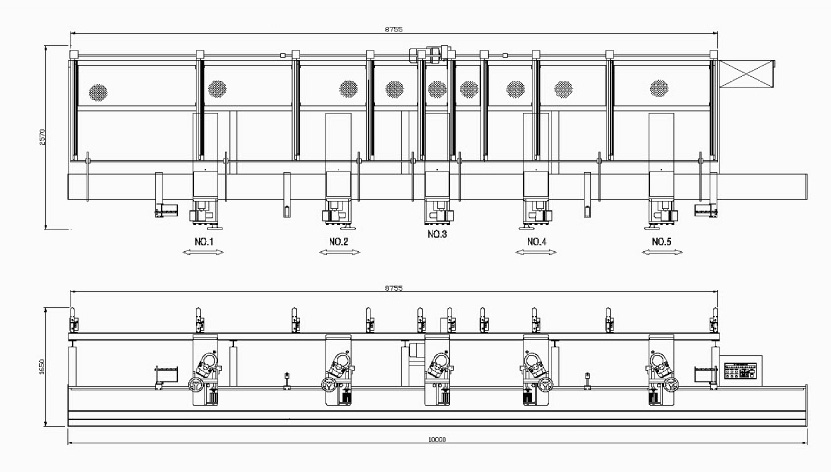

Description

Product Specifications

| Power consumption (kw) | 24kw | Head unit | 3.75kw X 5 |

|---|---|---|---|

| Supply table | 1.5kw X 1 | ||

| Compressor | 5.5kw X 1 | ||

| Electric | 220V / 380V 3Phase | ||

| Bending capacity | D10 ~ D32 | ||

| Bending angle | 15˚~ 180˚ | ||

| Working speed | 5sec/180˚ 6.3rpm | ||

| Supply table speed | 7.2m/min | ||

| Loading capacity (kg) | 2,500kg | ||

| Dimensions (m/m)(L×W×H) | 10,000×2,570×1,650 | L:possible adjustment | |

| Weight (kg) | 10,000kg | ||

Efficiency / No.of bars at one time

| Bar dia (mm) | D10 | D13 | D16 | D19 | D22 | D25 | D29 | D32 | Remarks |

|---|---|---|---|---|---|---|---|---|---|

| SD-400 | 12 | 9 | 6 | 4 | 3 | 2 | 1 | 1 | |

| Available roller specs | Ø49 | Ø49 | Ø62 | Ø74 | Ø84 | Ø94 | Ø104 | Ø114 |

One Day Productive Capacity (8hr)

| Patterns | bar dia (mm) | One time bending Q’ty | Per hour bending Q’ty | One day bending Q’ty | One day bending weight | Remarks |

|---|---|---|---|---|---|---|

|

D10 | 12pieces | 1080pieces | 1080×8=8,640 | 9,600kg | |

|

D13 | 9pieces | 810pieces | 810×8=6,480 | 13,000kg | |

|

D16 | 6pieces | 540pieces | 540×8=4,320 | 19,000kg | |

|

D25 | 2pieces | 260pieces | 260×8=2,080 | 48,000kg | |

|

D32 | 1pieces | 130pieces | 130×8=1,040 | 47,000kg |

Bending patterns

Plan