Product Features

- The productivity of steel Cutting can be increased in comparison with the standing manual system by more than 30 times (Refer to the daily work schedule.)

- It will be made easier to upload the steel products onto the steel-supplying table because the steel set-up safety system is applied in times of steel providing.

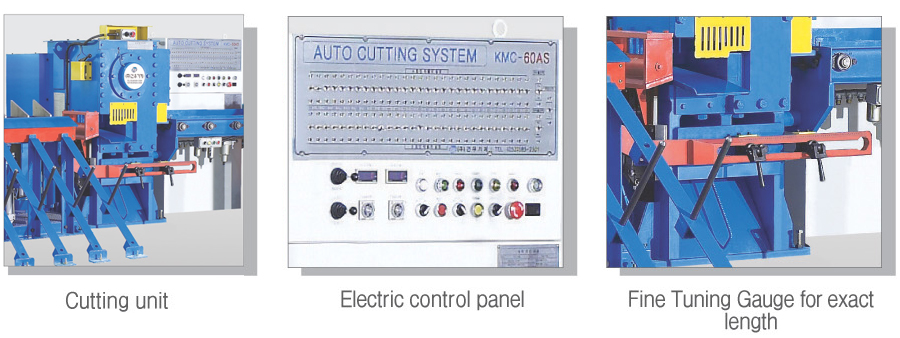

- As the main body of the machine consists of multi-stage gear and a powerful fly wheel, the steel Cutting and Bending process can be achieved easily and powerfully.

- With the Fine-distance Tuning Gauge, steel materials can be cut to minute measurements.

- Since the Automatic moving stopper props up the machine firmly, there in very little chance of errors taking place in measuring the steel length.

- The length of discharge table can be easily adjusted according to the conditions of an on-the-spot system.

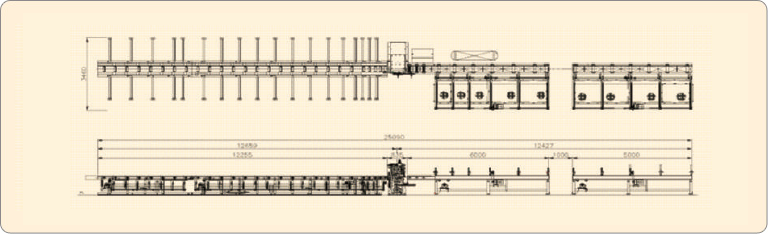

Description

Product Specifications

| Power consumption (kw) | 24kw | Head unit | 7.5kw×1 |

|---|---|---|---|

| Feed conveyor unit | 1.5kw×2 | ||

| Supple table | 1.5kw×4 | ||

| Compressor | 7.5kw×1 | ||

| Electric | 220V / 380V 3Phase | ||

| R P M | 27rpm | ||

| Feed conveyor speed | 49m/min | ||

| Blade dimension | 300mm×100×50 | ||

| Cutting length (mm) | 600 (min) ~ 12000 (max) | ||

| Supply table speed | 6.7m/min | ||

| Loading capacity | 6000kg | ||

| Dimensions (m/m) (L×W×H) | 25,090m×3,460×1,740 | ||

| Weights (kg) | 10,000kg | ||

Efficiency / No.of bars at one time

| bar dia (mm) | D10 | D13 | D16 | D19 | D22 | D25 | D29 | D32 | D35 | D38 | D41 | Remarks |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SD400 | 27 | 19 | 15 | 11 | 9 | 7 | 5 | 4 | 2 | 2 | 1 | |

| SD500 | 26 | 16 | 13 | 9 | 7 | 5 | 4 | 3 | 2 | 1 | 1 |

One Day Productive Capacity (8hr)

| bar dia (mm) | bar length | Cutting length | Cutting times | One time Cutting | No. of cut bars | Cutting weight | Remarks |

|---|---|---|---|---|---|---|---|

| D13 | 8m | 2m | 3 | 19 | 26,000PCS | 52,000kg | |

| D22 | 8m | 4m | 1 | 9 | 8,480PCS | 103,000kg |

Menu of touch screen

Plan